What Color To Print 3d Mini In

Are you looking to 3D print parts in colour or to create vibrant, multi-color parts? Over the last few years, multiple new methods have emerged to 3D print in color, and newer 3D printers have get more accessible, empowering any designer, model maker, or hobbyist to create objects in a range of hues.

In this guide, we dive into the several techniques you tin can use to produce colored 3D printed parts, also as the technologies and applications of color 3D printing.

There are several options to produce colored 3D printed parts, from color mixing to colour matching, full color 3D printing, painting 3D printed parts, and hydrographics.

Straight colour, likewise known as multicolor 3D printing is the most basic way to create 3D printed parts in various colors. It involves loading colored raw material into the printer. The most common way is using colored filaments with 3D printers that utilise fused degradation modeling (FDM) engineering science, which melts and deposits the filament onto the printer bed.

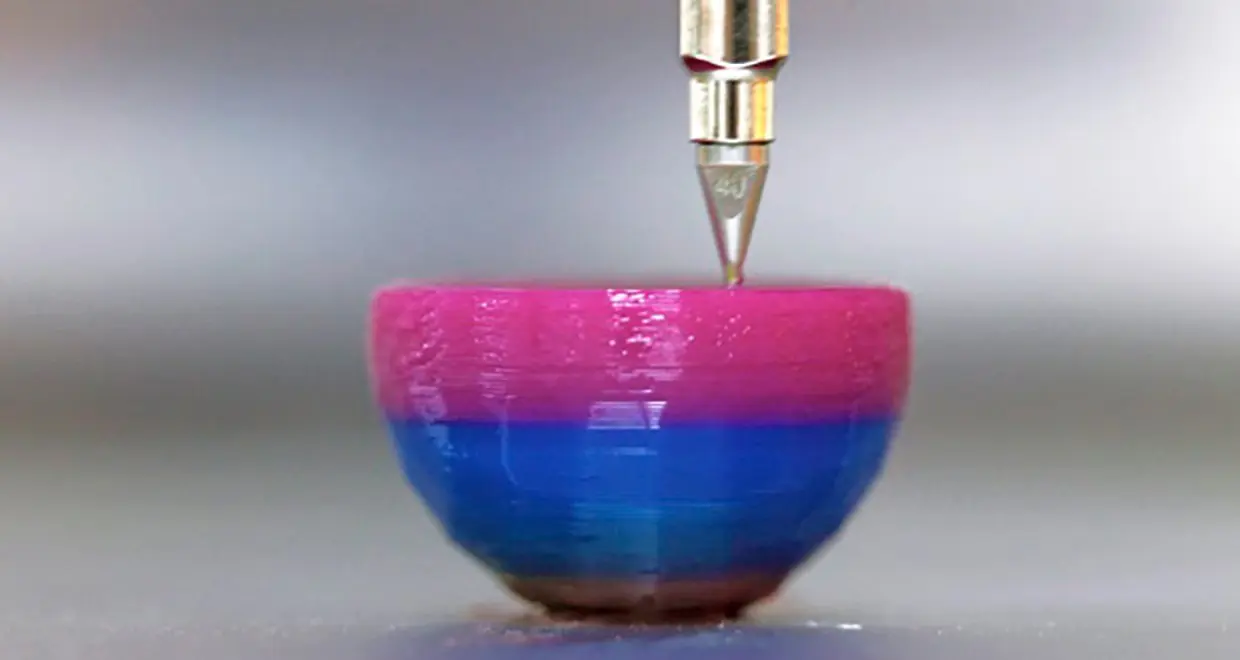

FDM 3D printing in colour. (source: 3Dnatives)

FDM 3D printers can print in a single color, using colored filament, in two colors, using a dual extruder, or in multiple colors and gradients using colour mixing, depending on how many filaments feed through the printer simultaneously.

The benefit of direct color 3D printing is that it is easy to use and affordable. However, the disadvantages are that information technology'southward not possible to accomplish a specific color tone, and the final office volition likely have visible layer lines. Too, the more than extruders an FDM printer has, the bigger the take chances of print errors.

While direct color press simply offers off-the-shelf color options, color matching allows you to create 3D printed parts in near any custom color.

SLA 3D printed parts in various custom colors.

As the first integrated color-mixing solution for stereolithography (SLA) 3D printing, Formlabs Color Kit mixes color pigments into the base textile to create a total cartridge of customized color resin. SLA 3D press then uses a laser to solidify the colored resin and create parts with a smooth surface cease and almost imperceptible layer lines.

Colour Kit, the starting time integrated colour-mixing solution for SLA 3D printing.

Full-colour 3D printing is the most versatile colour 3D printing method, as it produces objects in multiple colors at the aforementioned time, matching any tone and making realistic parts.

Unlike colored filaments or resin, the material used in full color printing is non pre-colored—the color is added to the base of operations fabric during the printing process, similar to a color 2nd printer.

Full-colored 3D printed role with folder jetting. (source: Hubs)

Technologies such as binder jetting and material jetting are able to produce full-colour 3D prints. However, these processes accept a loftier entry price, making them inaccessible to virtually users, while merely 1 manufacturer offers a more affordable full color FDM 3D printer.

In certain cases, colored 3D prints may lack the particular or the bright colors that an artist or designer aims for. Painting monochromatic 3D printed parts with acrylic, oil, or spray paint, while more than time-consuming, offers an inexpensive and fully custom solution.

Models that need a perfectly smooth terminate or very fine features may require postal service-processing techniques, such as sanding, priming, or using a solvent prior to painting.

Sanding reduces imperfections in the surface, and primer fills in small cracks and holes. Additionally, some 3D printed parts may need an undercoat to diminish the neutral color of the primer before the paint application.

Hydrographics, also known as hydroprinting, water printing, or water transfer printing, is a common method for applying printed designs to three-dimensional surfaces. The process uses an inkjet printer to impress an paradigm on a polyvinyl booze picture show. The film gets submerged in water and receives an activator chemical spray. The color motion-picture show so stretches over and adheres to the object as it's slowly dipped through the floating moving-picture show.

The nigh used technologies in color printing are FDM, SLA, SLS/MJF, binder jetting, and cloth jetting. Let's look at the pros and cons of each process.

FDM, or fused deposition modeling, is one of the most common and least expensive technologies in consumer 3D press. FDM 3D printers build parts past melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

Filaments for FDM printing in various colors. (source: All3DP.com)

FDM is more often than not used for direct color printing, with single extruder printers, or for color mixing 3D printing, with dual or multiple extruder printers.

FDM can now also exist used for total color 3D printing with the da Vinci Color 3D printer. With a colorless filament that is dyed using CMYK inkjet cartridges right before being extruded, it produces colored parts in a similar way to a color 2D printer.

SLA, or stereolithography 3D printing, uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization. SLA parts accept the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

SLA offers the possibility for colour matching almost whatsoever custom color using Formlabs Color Kit, the first integrated color-mixing solution for SLA 3D printing. Thanks to their smooth surface finish, SLA printed parts tin can also easily exist postal service-processed, painted, and used for applying hydrographics.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to larn how SLA printing works and why information technology'southward the nigh popular 3D printing procedure for creating models with incredible details.

Download the White Newspaper

Selective laser sintering is the well-nigh mutual additive manufacturing engineering for industrial applications, trusted by engineers and manufacturers across unlike industries for its ability to produce strong, functional parts.

Dyed SLS 3D printed parts. (source: Hubs)

SLS 3D printers use white, grey, or black nylon pulverisation as a raw material. While the parts cannot be directly printed in color, they can be dyed or painted in post-processing.

One exception to this is Multi Jet Fusion (MJF), which works similarly to SLS printers, but some MJF printers can besides selectively apply color ink on the powder layer, making it possible to print strong total colored 3D printed parts. Nevertheless, the entry price for this applied science is significantly higher.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to larn how SLS printing works and why information technology'due south a popular 3D press process for functional prototyping and end-use production.

Download the White Newspaper

The binder jetting 3D press technology is similar to SLS and MJF printing simply uses a colored bounden agent to bond powdered sandstone material instead of heat.

Parts produced with binder jetting take a porous surface and are very brittle, which ways that this procedure is recommended but for static applications, such equally creating full-color figurines and concept models.

Figurines printed with folder jetting. (source: Shapeways)

Material jetting 3D printers combine traditional inkjet press with the apply of photopolymer resins, by depositing droplets of the material on a build tray like to second printers, which then gets hardened past UV light.

This process offers a myriad of colour possibilities and can create photorealistic parts with vibrant colors. However, the parts accept poor mechanical properties, are estrus-sensitive, and the entry price for this technology is the highest of all color 3D printing options.

Color 3D printing with material jetting. (source: Hubs)

| FDM | SLA | SLS / MJF | Binder Jetting | |

|---|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Clarification | The print head melts and extrudes thermoplastic filament | A laser solidifies liquid resin | A laser or light source sinters nylon pulverization | A binding agent bonds sandstone powder |

| Materials | Thermoplastic filaments | Varieties of liquid resin | Varieties of polymer powder | Sandstone |

| Color 3D press options | Direct colour, color mixing, or full colour | Color matching | None / Full colour | Full color |

| Post-processing with colors | Painting (requires a lot of postal service-processing) Hydrographic printing | Painting Hydrographic printing | Dyeing Painting Hydrographic printing | Painting Hydrographic printing |

| Applications | Basic modelmaking | Rapid prototyping, miniatures and models, medical models | Rapid prototyping, end-use parts | Miniatures and models |

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, nosotros compare FDM, SLA, and SLS technologies beyond popular ownership considerations.

Watch the Videos

Color 3D printing empowers engineers and designers to salve money and time with looks-like prototypes, moving picture makers to plow digital models into props, model makers to create vibrant miniatures, medical professionals to produce accurate anatomical models, and more than.

Rapid prototyping helps companies turn ideas into realistic proofs of concept, advances these concepts to high-fidelity prototypes that await and work similar last products, and guides products through a serial of validation stages toward mass production.

Concept models in color tin can demonstrate an thought to stakeholders, create word, and drive acceptance or rejection using low-gamble concept explorations.

At subsequently stages, realistic looks-like prototypes in color tin give a better idea of what an end product will look like and how the end-user volition interact with information technology. Ergonomics, user interfaces, and overall user experience can be validated with 3D printed looks-like prototypes before spending meaning design and applied science time to fully build out product features.

Colour matching 3D printing or full color 3D printing likewise allows product development teams to experiment with different colour options and run studies with customers before moving into product.

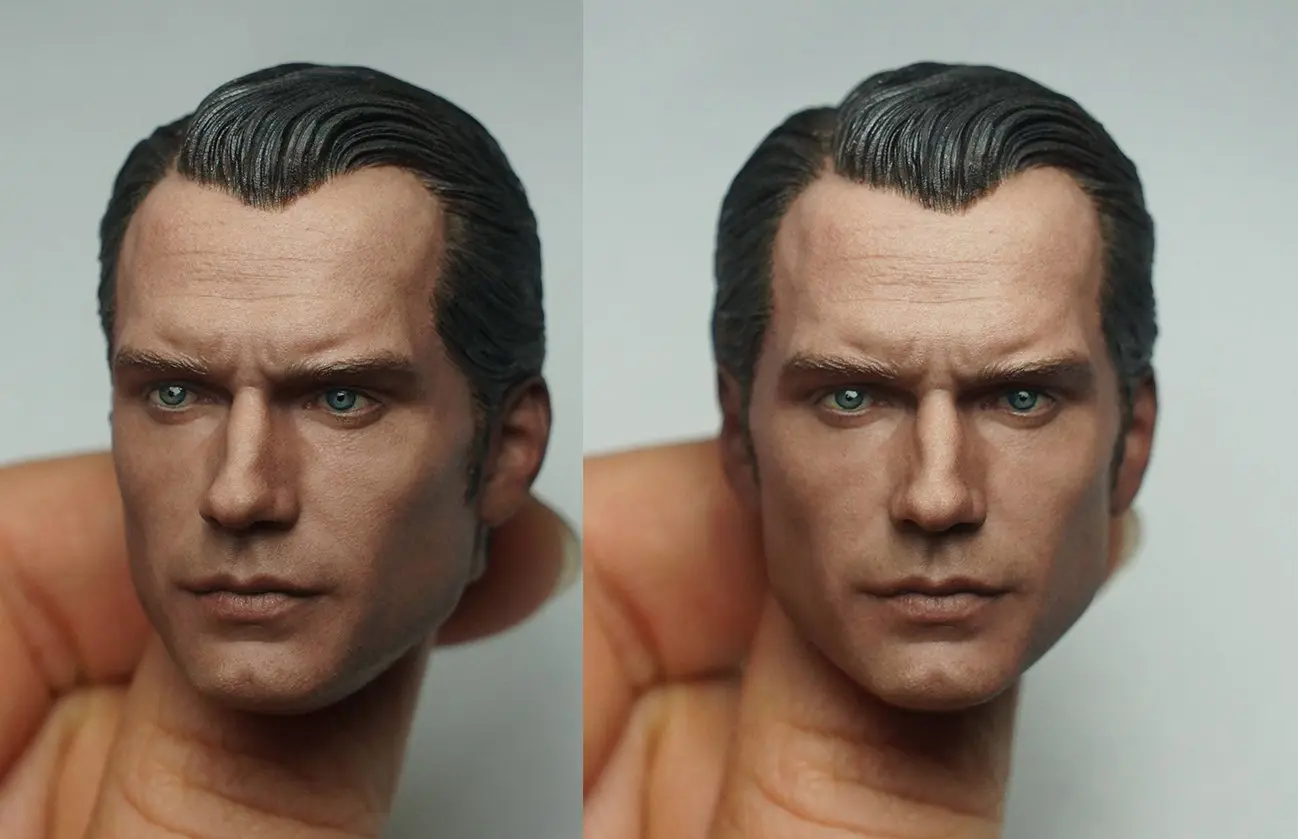

In the entertainment manufacture, 3D printed props and models are blurring the line between physical models and digital effects. Artists create realistic, detailed models using 3D modeling software and then bring them to life in a affair of hours using 3D printing. Loftier-resolution 3D printing processes, like SLA, can reproduce even the almost complex parameters of a design, such equally skin texture.

A behind-the-scenes look at visual effects (VFX) and design studio Aaron Sims Creative's process to design of Stranger Things' Demogorgon.

Props masters, such every bit Russell Bobbitt for Curiosity movies and Jaco Snyman for the Raised by Wolves series, too as visual effects (VFX) and design studio Aaron Sims Artistic for Stranger Things, accept adopted the engineering, as it significantly saves time in prop making and fuels creativity in the design process. The cosmos becomes more than flexible and fluid, and props and models tin be created in an efficient manner.

Without a dubiety, 3D printing has revolutionized the cosmos of custom miniatures and figurines, whether for model making, tabletop games, collectibles, or other hobbies.

As full-color 3D printers are frequently out of budget for hobbyists and model makers traditionally hand-paint models anyway, the most popular mode to create colorful models is to paint them after 3D press.

For case, artists at Modernistic Life Workshop combine 3D modeling blueprint with SLA 3D printing to create hyper-realistic glory portraits. The artists use the digital freehand sculpting software ZBrush to create detailed models on the computer. Then, they 3D impress the designs on an SLA 3D printer and pigment the parts by mitt.

In gaming, online communities have sprung upwardly effectually tabletop games similar Dungeons & Dragons, for which gamers utilize 3D printers to create i-of-a-kind D&D 3D printed miniatures, figurines, terrains, landscapes, and other board game accessories.

Professional model-making companies, like DM-Toys, also employ 3D press to accelerate prototyping and production cycles of custom models.

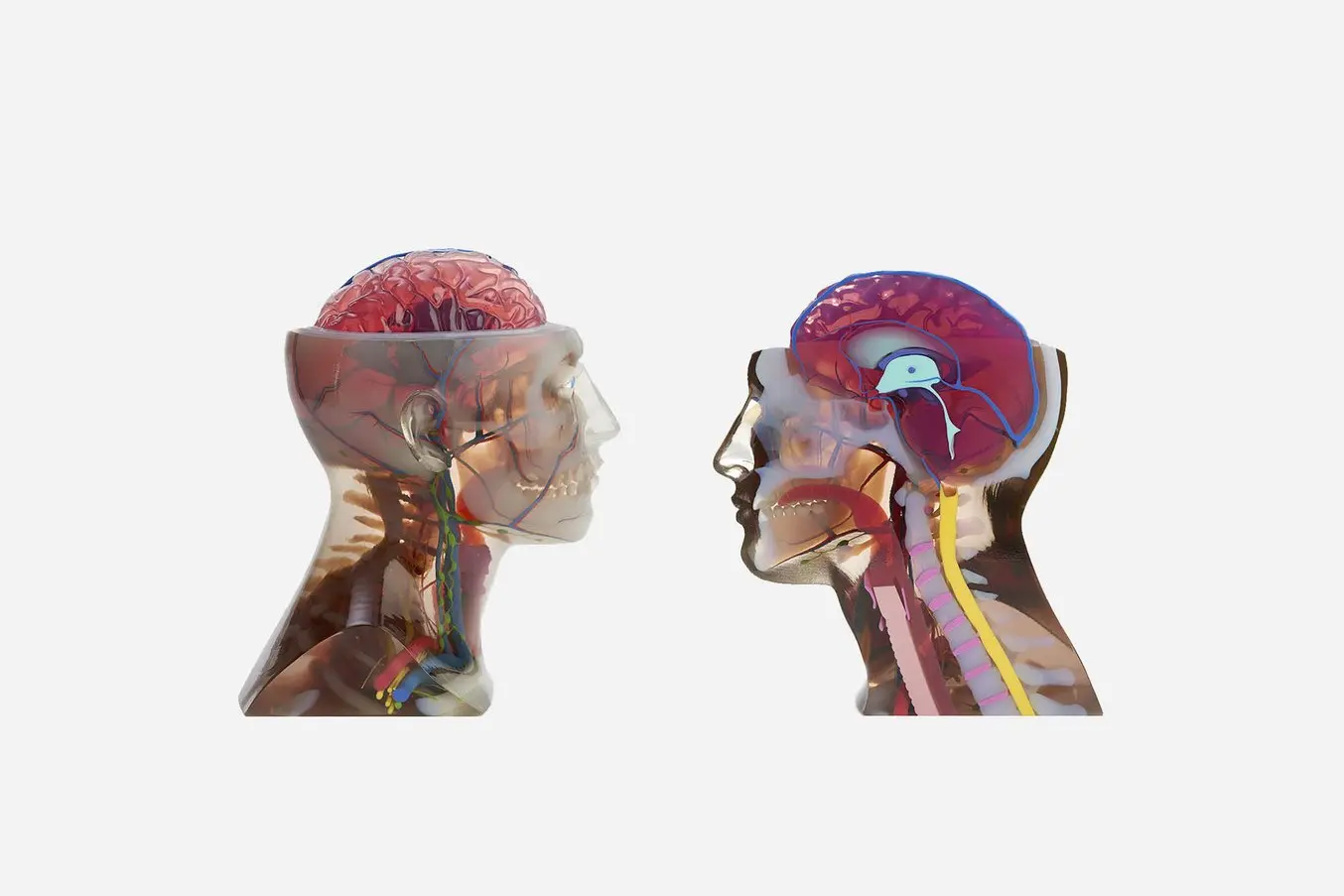

In healthcare, radiologists, surgeons, and biomedical professionals are increasingly turning to 3D printing to create accurate 3D models of anatomical features that tin can exist used every bit reference tools for preoperative planning, intraoperative visualization, and education.

3D printing empowers medical professionals to create complex models with intricate details that would be impossible to produce with other technologies.

High-detailed color models are excellent in resident education programs, where each blood vessel or organ can be directly 3D printed or painted in different colors for easy classroom viewing.

Furthermore, patient-specific surgical models that are based on patient scan data are becoming increasingly useful tools in today'south do of personalized, precision medicine.

Whether it is color matching to create 3D printed parts in almost whatsoever custom color, or printing loftier-resolution parts that can be painted to create hyper-realistic models, SLA 3D printing delivers incredible detail and seamless performance at an affordable price signal.

Start 3D printing your own 3D printed parts on the Class 3 and bring your biggest ideas to life with the Class 3L.

Source: https://formlabs.com/blog/guide-color-3d-printers/

Posted by: renfrofould1991.blogspot.com

0 Response to "What Color To Print 3d Mini In"

Post a Comment